What Is WOS In Retail? How to Calculate + Pros & Cons

Published: 09 Mar 2025

In retail stores, proper inventory management is so crucial to ensure customers always stay happy and store owners secure handsome profits.

But how do you know if you have too much stock or not enough? This may be a little bit tricky right?

But guys, you don’t need to worry about it because I’ve brought a proven solution for you and that is WOS or Weeks of Supply.

Weeks of Supply (WOS) is a powerful inventory management metric that helps us find out how long our current inventory will last based on sales.

But some main questions,

- How do you calculate weeks of supply (WOS)

- Why it’s important for us

- What are the advantages and downsides of the Weeks of Supply (WOS)

- How can it shape our businesses?

Guys, now you might be wondering about these questions, right? Don’t worry I’ve got you covered.

Let’s come and explore each point one by one.

What Is WOS In Retail?

WOS simply stands for weeks of Supply.

It’s a powerful inventory management strategy that millions of people use to figure out how long their current stock will last based on weekly sales and historical demand.

In practical terms, WOS calculates the number of weeks your existing inventory will meet customer demand before requiring replenishment.

For example, if you have 1,000 units of a product and you sell 100 units per week (1,000/100 = 10), your weeks of Supply (WOS) is 10 weeks.

This means you have enough inventory available for almost 10 weeks; after that, you will need replenishment.

That’s said!

Why Calculating Weeks of Supply (WOS) Is Important?

Calculating Weeks of Supply is crucial for all retailers with various aspects. For example;

- Calculating Weeks of Supply (WOS) helps you keep just the right amount of stock—no more guessing.

- It ensures you never run out of products, so customers stay happy and sales keep growing.

- WOS gives you a clear picture of how long your inventory will last, making planning easier.

- It saves money by preventing overstocking, which ties up cash and increases storage costs.

- With WOS, you can prepare for busy seasons or sales spikes without stress.

- It helps you build stronger relationships with suppliers by ordering at the right time and avoiding misconceptions and confusion.

- Ultimately, WOS keeps your business growing, boosting both profits and customer trust. Now let’s come and understand how to calculate your store’s weeks of supply (WOS).

How Do You Calculate Weeks of Supply?

Guys, you have two ways available to calculate your store’s weeks of supply.

- WOS (weeks of supply) formula

- FWOS (Forward weeks of supply) formula.

Both approaches provide valuable insights into your inventory health.

Now let’s explore each method one by one.

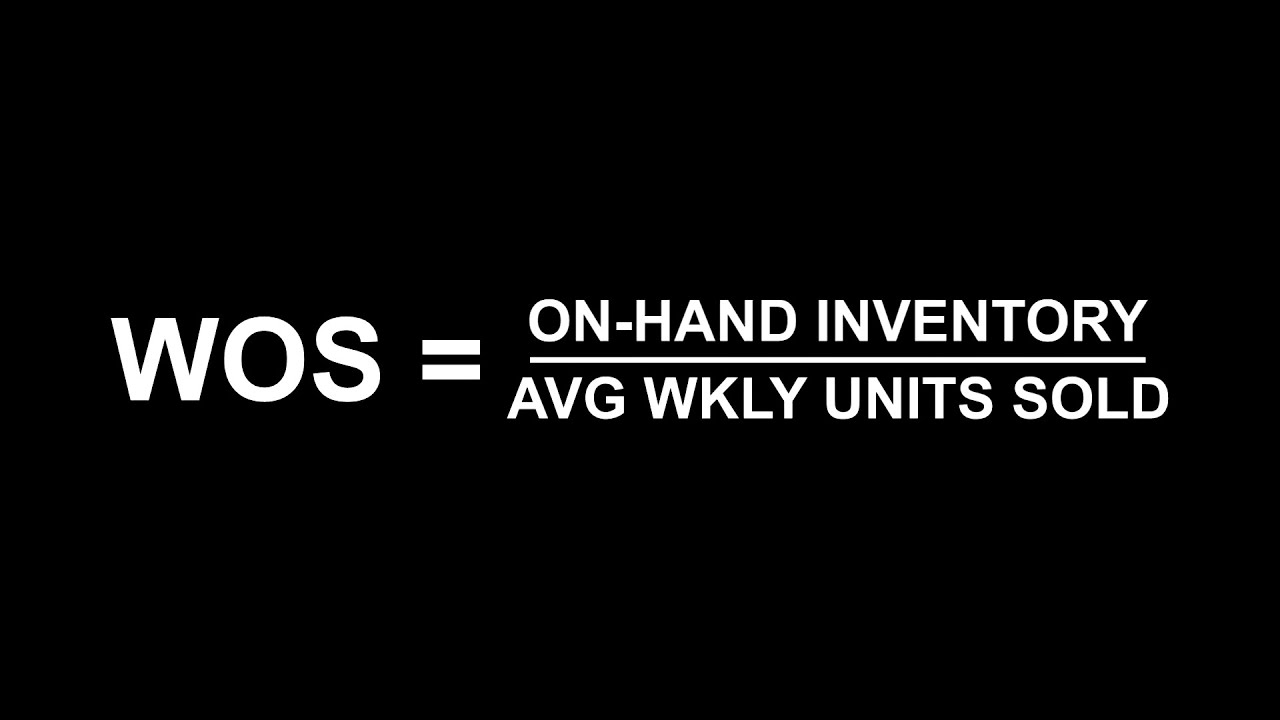

WOS Formula (Weeks of Supply)

The WOS formula calculates how long your current inventory will last based on historical sales data.

It’s a straightforward and widely used method for inventory planning.

The formula which we often use to calculate WOS using the WOS formula is

- WOS = Current Inventory (in units) ÷ Average Weekly Sales (in units)

Let’s take a quick example of it.

For example, you have 400 units of a product in stock, and your average weekly sales over the past month have been 40 units per week. So when applying the formula,

- WOS = 400 ÷ 40 = 10 weeks

This means your inventory will last for 10 weeks at the current sales rate.

I’d recommend you use the WOS formula when;

- Your sales patterns are stable and predictable.

- For quick, routine inventory assessments.

- You lack access to advanced forecasting tools or systems.

- You’re managing non-seasonal products with consistent demand.

- You need a simple starting point for inventory planning.

- You’re running a smaller business with less complex inventory needs.

- You want to perform a basic check on how long your current stock will last.

FWOS Formula (Forward Weeks of Supply)

The FWOS formula takes a more proactive approach by using future demand forecasts to determine how long your inventory will last.

This method is particularly useful for businesses with seasonal trends or planned promotions.

The formula which we usually use is

- FWOS = Current Inventory (in units) ÷ Forecasted Weekly Demand (in units)

Here is an example of how to calculate Weeks of Supply (WOS) using the FWOS formula.

Let’s say you have 1,000 units of Christmas lights in stock, and next month is Christmas.

Based on historical data and market trends, you forecasted that demand will increase to 250 units per week during the holiday season.

So using the FWOS formula:

- FWOS = 1,000 ÷ 250 = 4 weeks

This means your current inventory of Christmas lights will last for 4 weeks based on the forecasted demand.

I’d recommend you use the FWOD formula when managing inventory, especially for

- seasonal periods (e.g., holidays, festivals).

- For products with fluctuating demand patterns.

- When planning for promotions or sales events.

- Or doing businesses with highly variable sales trends.

Weeks of Supply (WOS) vs. Forward Weeks of Supply (FWOS)

Weeks of Supply (or WOS) and Forward Weeks of Supply (or FWOS) are both closely related but a little bit different metrics when it comes to their use and purpose.

The primary difference lies in the data they use:

- WOS relies on historical sales data to determine how long your current inventory will last, making it ideal for businesses with stable, predictable sales patterns.

- On the other hand, FWOS uses future demand forecasts to predict inventory longevity, offering greater accuracy for businesses with seasonal trends, promotions, or fluctuating demand.

WOS is simpler to calculate and is often used for routine inventory checks, while FWOS requires more advanced forecasting comprehension and is better suited for strategic, forward-looking planning.

In practice, WOS is a great choice for non-seasonal products or consistent sales environments, whereas FWOS is the best option when preparing for seasonal peaks, promotions, or unexpected demand shifts.

Disadvantages of WOS.

Weeks of Supply (WOS) offers a lot of benefits when it comes to proper inventory management.

But as a fact, nothing is perfect here, right? So weeks of supply also have some downsides including;

- Backward-Looking Approach: This relies on historical sales data, which may not capture future market trends or shifts in consumer preferences.

- Struggles with Volatility: In industries with unpredictable demands, like fashion and event-based shops, WOS can lead to either overstocking or stockouts due to its inability to adapt quickly.

- Limited Scope for Innovation: For new or innovative products, WOS may not provide accurate insights due to a lack of historical sales data.

- Misses External Dynamics: WOS doesn’t account for external factors like competitor launches, economic downturns, or sudden supply chain disruptions.

- Inadequate for Short-Term Planning: WOS is better suited for long-term trends and may not be effective for short-term inventory adjustments or flash sales.

- Risk of Misinterpretation: Without proper context, WOS calculations can be misleading, especially if sales data is inconsistent or incomplete.

Hey My Dears.

So today, we’ve explored WOS (Weeks of Supply) in retail, how to calculate it, and why it’s so important for managing inventory.

We also touched on FWOS (Forward Weeks of Supply), which uses future demand forecasts for more accurate planning.

Whether you’re managing a small shop or a large store, understanding WOS and FWOS can help you avoid stockouts, reduce overstocking, and keep your customers happy.

Use WOS for stable sales and FWOS for seasonal or promotional planning.

By mastering these tools, you’ll make smarter decisions and grow your business with confidence.

If you found this helpful, share it with others, and feel free to reach out with any questions!

Until next time, happy selling!

FAQs About WOS.

These are some questions related to weeks of supply.

WOS stands for Weeks of Supply. It’s a metric used in retail to measure how long your current inventory will last based on sales. For example, if you have 100 units and sell 10 per week, your WOS is 10 weeks.

You can use simple spreadsheets like Excel or Google Sheets to calculate WOS manually. For more advanced needs, inventory management software like Toolio or TradeGecko can automate the process and provide real-time insights.

It’s best to calculate WOS regularly, such as weekly or monthly, depending on your sales cycle. Frequent calculations help you stay on top of inventory changes and adjust your plans as needed.

Yes! By avoiding overstocking, WOS helps you maintain optimal inventory levels, reducing excess storage costs. It ensures you only keep what you need, freeing up space and capital.

If your sales data is inconsistent, consider using a longer time frame (e.g., 8-12 weeks) to calculate average weekly sales. This smooths out irregularities and provides a more accurate WOS.

WOS helps ensure you always have enough stock to meet customer demand, preventing stockouts. Happy customers mean repeat business and positive reviews, boosting your store’s reputation.

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks

- Be Respectful

- Stay Relevant

- Stay Positive

- True Feedback

- Encourage Discussion

- Avoid Spamming

- No Fake News

- Don't Copy-Paste

- No Personal Attacks